It has been a whirlwind here in the Lever household the last couple of days.

It all started with a trip to Matt’s shop to drop off some used oil. See the last entry under the biggest news.

BIG NEWS I have contacted Dan of Dishon’s Transmissions, a contributor on my forum.

http://www.frontenginedragsters.org/forum/

He has agreed to build the Turbo 400 for Anne’s gasser.

BIG NEWSWe had Paul Francia (Known as Uncle Paul) over. He was a wealth of knowledge.

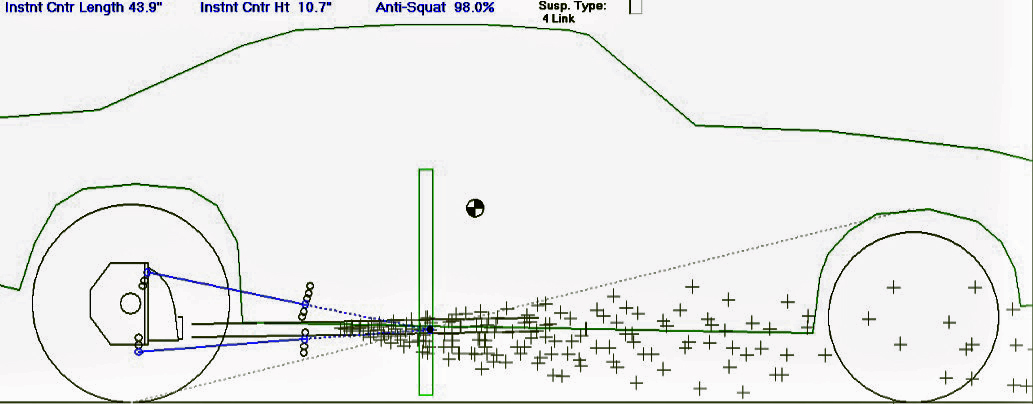

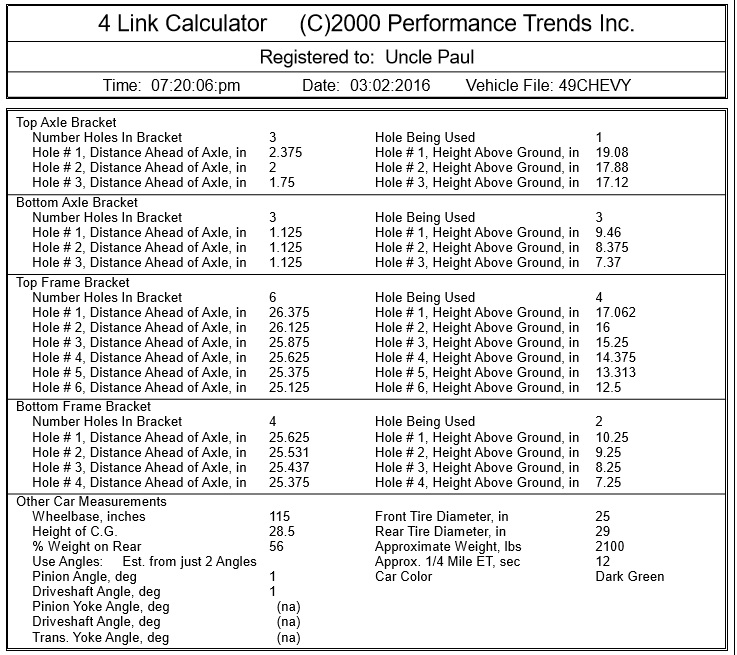

He entered all the locations and pertinent information into his Four Bar program. We learned that the bars needed to be set up completely different from what they were.

With the current set up, there is lots of adjustability to the instant center of gravity.

With the new configuration of the bars we have 98% Anti Squat.

THE BIGGEST NEWS

THE BIGGEST NEWSAt Matt’s shop, I was introduced to Walter Cotturone who is also into Pontiac engines.

He informed me that Butler had a sale going on, on their aluminum block.

$600.00 off was quite an enticement. I am currently at the limit of the stock cast iron block in the dragster and everyone knows what happens when you run at the limit.

It comes with keyed steel main caps studs and the outer bolts are splayed.

I thought I had on hand all the internal components to build a 428 Pontiac blower engine.

I thought I had on hand all the internal components to build a 428 Pontiac blower engine.So…we are off to the races, many phone calls, text messages, and e-mails later and we learned that we were not as close as we thought.

My Venolia Pistons will not work in the Aluminum block as they are for a 4.155 bore and the sleeves in the aluminum block start at 4.250 (pistons are too small).Butler informed me their aluminum block comes machined for a 50MM cam so the cam I have will not work (but wait, read on). Upon questioning, it was found out that the drive shaft for the oil pump in the aluminum block is an inch longer than stock and costs $32.00.

Butler would not give us a deal for the purchase of two blocks together.

More phone calls.

So…I found out that Butler purchases from AllPontiac.com

http://allpontiac.com/ I looked them up and called the number on the web site. I ended up talking with the owner Frank Gostyla.

Learned some more stuff.

1) The block comes as a dry deck; no holes for the water jacket in the block to the heads. There are extra ports in the water jacket from the block to allow running lines from those ports to the rear ports on the heads. Or the deck can be drilled to allow normal water passage. Current thought is to retain the dry deck.

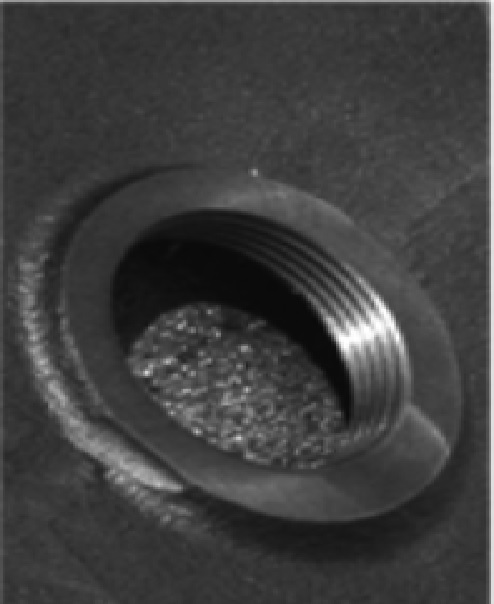

2) The freeze plugs in the side of the block are threaded and require a threaded plug.

3) Frank was willing to work a deal for the purchase of two blocks. He gave us free shipping to a commercial address. He included the drive shaft for the oil pump for free and he offers the aluminum blocks with either the stock bore for the cam or the 50MM bore for the roller cam bearings.

4) These blocks are not on the shelf, but currently being cast. Lead time is currently 5 to 6 weeks.

5)

So this phone call saved me having to buy a new cam, saved the shipping costs, and saved me the cost of the oil pump drive shaft. I did purchase the threaded plugs for the freeze plug holes for $85.00. Yes, that is right. We have purchased the aluminum block6) Deal is done now. We are in like Flint, right, just wait, are you kidding? This is hard luck Glenn.

My internal parts were purchased a long time ago for a blower engine that never got built. So those parts have been on the shelf a long time. Now I’m going through them and learning their fitments.

In that process, I e-mailed RPM (the vendor of the crankshaft I have). They sent me this information: “RPM P/N# DG3-455A400C is 4340 forged steel for 361-400 Pontiac with 4.0" stroke 3.00" MJ / 2.20" RJ ; External balance can hold up to 850hp.”

The thing to note is they say hold up to 850hp which will not work. We are looking for 1,000 HP with room to grow so that when ready we can move into Steve Walczak’s kingdom of 7.000

Their statement does not make sense when compared with the information on their web site which is:

“RPM International offers three distinct types of crankshafts—Cast, 4130/5140 Forged with Nitriding, and the SAE 4340 Forged with Nitriding, which is our top of the line.

SAE Certified 4340 forged material is used for superior strength and its proven performance in the aircraft and aerospace industries. For increased strength these cranks are given a second heat treatment after rough finishing and then nitride hardened eliminating any deformation after leaving the factory.”

As I have the 4340 crankshaft, how can it be rated for only 850 HP? I asked that question and received this answer.

“This crank is the top level of 4340 Chrome-moly-nickel material we imported from overseas for years. They did the dyno testing there with 850hp @7000rpm from the original designed(sp) and it's the numbers which provided from the manufacturer. “

So right now it looks like the pistons absolutely will not work, the Crankshaft is not going to work, and

Frank of AllPonitac says I should consider a longer rod to get a better rod length to stroke ratio.Anyone want a complete brand new in the box rotating assembly (Venolia rods and Pistons RPM 4340 Crankshaft) for a 428 Pontiac?

MORE BIG NEWSWe have decided to move ahead. I have talked with Al of Freedom Racing Engines

http://freedomracingengines.com/

out in Brownsburg, IN (same town Keith Burgan is from builder of the dragster).

Freedom Racing Engines is a supporter of NDRL the racing series that we race in.

http://www.nostalgiadragleague.com/ He has agreed to assemble the engine, look at all the misc parts and make a cohesive engine. This engine will easily put us into the 7.5 class with room to go to 7.0 and have the engine live a happy long life.